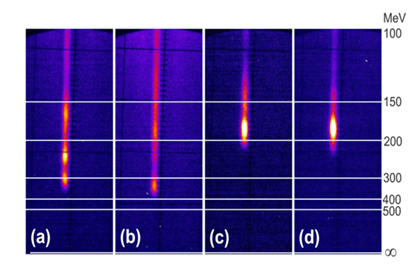

Electrons acceleration by laser-plasma interaction in ultra-intense regime

At the interaction between ultra-intense laser pulses and supersonic gas jets, a plasma filament is generated with the property of generating electron beams accelerated at energies of the order of hundreds of MeV, comparable to the energies obtained in large particle accelerators. At CETAL, for the first time in Romania, such experiments were performed that open the way to various applications, such as laboratory simulation of cosmic radiation in order to test equipment for space missions or medical applications of electron beams for oncological treatments. The team from the CETAL-PW laboratory demonstrated the electron beams with good spatial and temporal stability, with energies up to 500 MeV for laser pulses with peak power below 100 TW.

Reference: C. Diplasu, G. Giubega, R. Ungureanu, G. Cojocaru, M. Serbanescu, A. Marcu, E. Stancu, A. Achim, M. Zamfirescu, Commissioning experiment on laser-plasma electron acceleration in supersonic gas jet at CETAL-PW laser facility, Romanian Reports in Physics 73, 401 (2021).

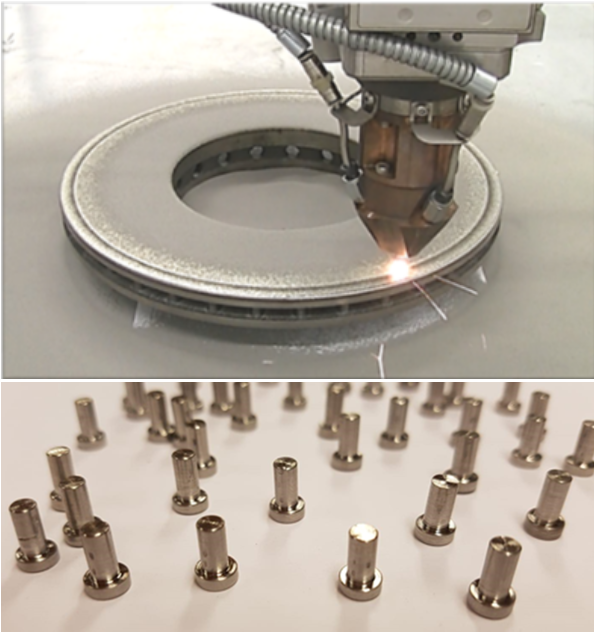

Laser additive manufacturing of 3D metal parts

The CETAL Center is a pioneer in Romania in the development of technologies based on the additive manufacturing of metallic and metal matrix composite materials by laser directed energy deposition methods. The CETAL-LaMP laboratory conducts both fundamental research in national research projects, as well as industrial research, in collaboration with national companies that aim to develop and implement additive manufacturing technologies for the development of innovative products. Research in the field includes the manufacture of custom implants and prostheses for biomedical applications, laser plating for functional coatings in the automotive industry, embossing with metallic materials, development of equipment for in situ monitoring of manufacturing processes with laser sources, welding with additive material or fabrication of shapes using generative design programs. The additive manufacturing process is monitored in real time by fast camera imaging for the study of laser plasma and expelled liquid material, as well as by thermography, using thermal cameras to determine the temperature in the processing area and heat distribution in the material. The laboratory is equipped with metallographic characterization equipment for highlighting the metallic phases, studying the distribution of the dispersed phase in the metallic matrix and identifying possible processing defects (cracks and pores).

Reference: Chioibasu, Diana, Sabin Mihai, Muhammad A. Mahmood, Mihail Lungu, Ioana Porosnicu, Adrian Sima, Cosmin Dobrea, Ion Tiseanu, and Andrei C. Popescu 2020. "Use of X-ray Computed Tomography for Assessing Defects in Ti Grade 5 Parts Produced by Laser Melting Deposition" Metals 10, no. 11: 1408. https://doi.org/10.3390/met10111408.

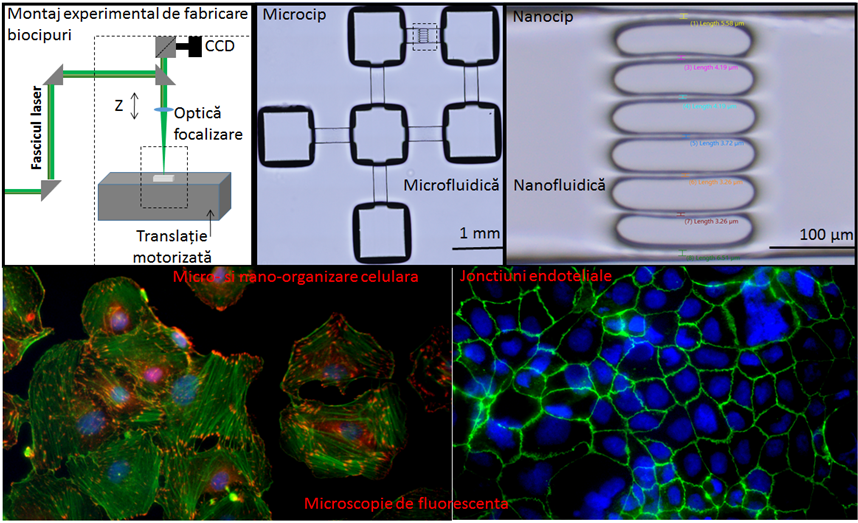

Microfluidic devices for investigating cellular mechanisms and bio-sensors

At CETAL, nanophotonic technologies are developed for the processing of transparent materials for Lab-on-Chip applications. Thus, we make microfluidic circuits with nano-dimensional characteristics in photosensitive glasses and polymers. In the biology laboratory, various types of cells are seeded in these devices and their behavior is analyzed using a dual microfluidics and imaging station by 4D fluorescence microscopy. The aim is, on the one hand, to study the mechanisms of cancer cell metastasis and, on the other hand, to develop a blood-brain barrier model for Alzheimer's disease.

References: Felix Sima, Koji Sugioka, “Ultrafast laser manufacturing of nanofluidic systems”, Nanophotonics 10 (9) 2389–2406 (2021); Cristina E Staicu, Florin Jipa, Emanuel Axente, Mihai Radu, Beatrice M Radu, Felix Sima; “Lab-on-a-Chip Platforms as Tools for Drug Screening in Neuropathologies Associated with Blood–Brain Barrier Alterations”, Biomolecules 11 (6), 916 (2021).